He aha ka Metal Die Casting?

ʻO ka Die Casting e pili ana i ke kaʻina hana o ka hana ʻana i nā ʻāpana metala i hoʻokumu ʻia e kahi mol.Hāʻawi kēia kaʻina hana i nā huahana e hana ʻia ma ke ʻano hana nui me ka kiʻekiʻe kiʻekiʻe a me ka hana hou.Hoʻomaka ke kaʻina hana ma ke koi ʻana i ka metala i hoʻoheheʻe ʻia ma lalo o ke kaomi kiʻekiʻe i loko o kahi pahu make.Hiki i ka make ke komo i hoʻokahi a i ʻole nā lua he nui (ʻo nā lua ka poʻe i hana i ke ʻano ʻāpana).I ka wā e paʻa ai ka metala (e like me ka wikiwiki o 20 kekona) a laila wehe ʻia ka make a wehe ʻia ka pana (nā ʻīpuka, nā kukini a me nā ʻāpana pili) a hoʻomaka hou ke kaʻina hana.Ma hope o ka hana hoʻoheheʻe ʻana, hoʻomaʻamaʻa pinepine ʻia ka pana ʻana ma kahi ʻoki make kahi i wehe ʻia ai nā puka, nā kukini a me ka uila.A laila hiki ke hana hou ʻia ka ʻāpana e ka vibratory deburring, shot blasting, machining, pena pena, etc.

Pono o Die Casting

ʻO ka hoʻoheheʻe alumini ka hana maʻamau e hana i nā ʻāpana hoʻoheheʻe alumini i hoʻohana ʻia i nā ʻoihana like ʻole.ʻOiai ʻo ka alumini he mea maikaʻi loa ka flowability, ke kūpaʻa corrosive a me ke kūpaʻa kiʻekiʻe me nā ʻāpana paʻakikī.

ʻO ka ʻāpana hoʻoheheʻe alumini ka ikaika mechanical kiʻekiʻe, maʻalahi ka hoʻolei ʻana, a he haʻahaʻa haʻahaʻa ke kumukūʻai i hoʻohālikelike ʻia i nā ʻāpana hoʻoheheʻe zinc a i ʻole magnesium.

Loaʻa nā ʻāpana hoʻoheheʻe alumini i nā waiwai kino e kū i kahi wela kiʻekiʻe, e hiki ai ke hoʻohana ʻia ka hoʻolei alumini i nā kaʻa, mokulele, lāʻau lapaʻau, a me nā huahana ʻoihana ʻē aʻe.

ʻElima ʻanuʻu

KaʻAnuʻu 1. Mea hoohehee

No ka mea he wahi hehee kiʻekiʻe loa ka alumini (660.37 °C) ʻaʻole hiki ke hoʻoheheʻe ʻia i loko o ka mīkini hoʻoheheʻe make.ʻO kēia ke kumu e pono ai mākou e hoʻoheheʻe mua iā ia me kahi kapuahi i hoʻopili ʻiahe mīkini hoolei make.

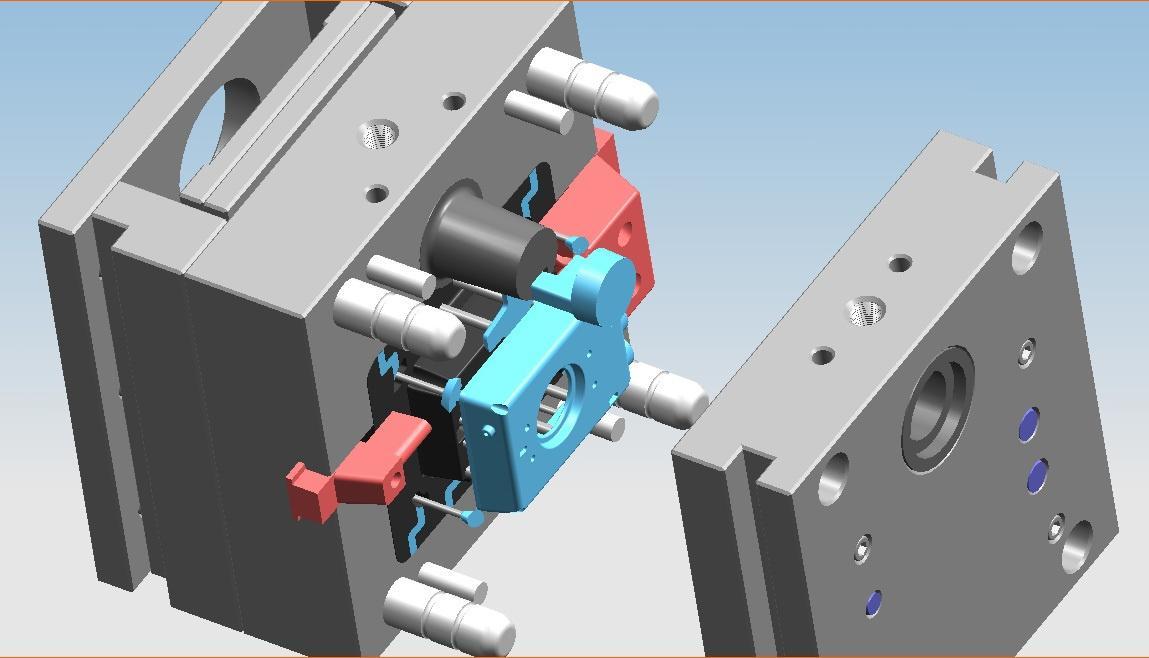

KaʻAnuʻu Hana 2. Mold mea paahana kau a me Clamping

Aneane like me ka hoʻoheheʻe ʻia ʻana, pono nō hoʻi ke kaʻina hoʻoheheʻe make i kahi mea hana no ka hoʻolei ʻana.No laila, pono mākou e kau i ka mea hoʻoheheʻe hoʻoheheʻe make ma luna o kahi hoʻolei anumīkini.

KaʻAnuʻu 3. Injection a hoʻopiha

Hoʻololi ʻia ka mea hoʻoheheʻe ʻia mai ka umu ahi i ka mīkini hoʻoheheʻe make e ka ladle neʻe.I kēia pae, e ninini ʻia ka mea i loko o ka lua hoʻoheheʻe make i kahiʻoluʻolu a paʻa ka mea e loaʻa ai nā huahana hoʻolei make.

KaʻAnuʻu 4. Cool a Solidification

Ma hope o ka hoʻopiha piha ʻana o ka mea hoʻoheheʻe make me nā mea hoʻoheheʻe ʻia, pono ʻo 10 ~ 50 kekona e hoʻomaʻalili a paʻa (e pili ana i ka ʻāpana a me ka nui).

KaʻAnuʻu 5. Part Ejection

Ke wehe ʻia ka ʻōpala, e hoʻokuʻu ʻia nā ʻāpana i hoʻolei ʻia e nā pine ejection mai ka mea hana hoʻoheheʻe make.A laila ua mākaukau nā ʻāpana i kālai ʻia.

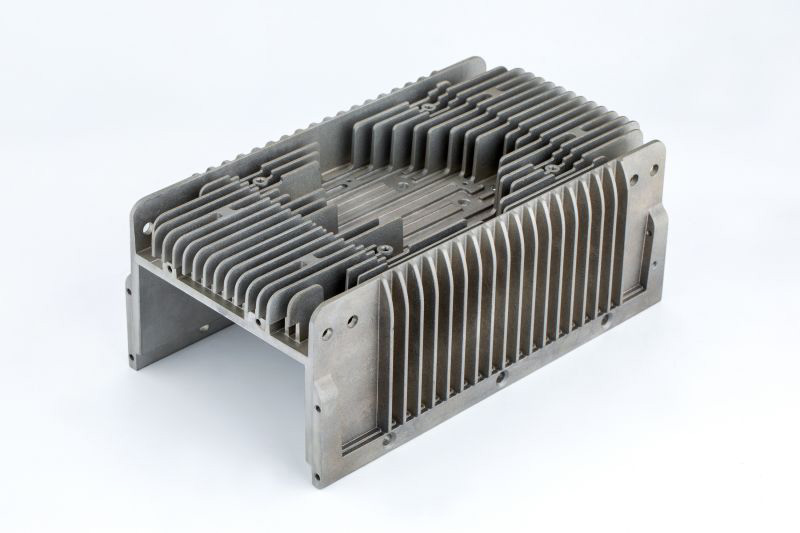

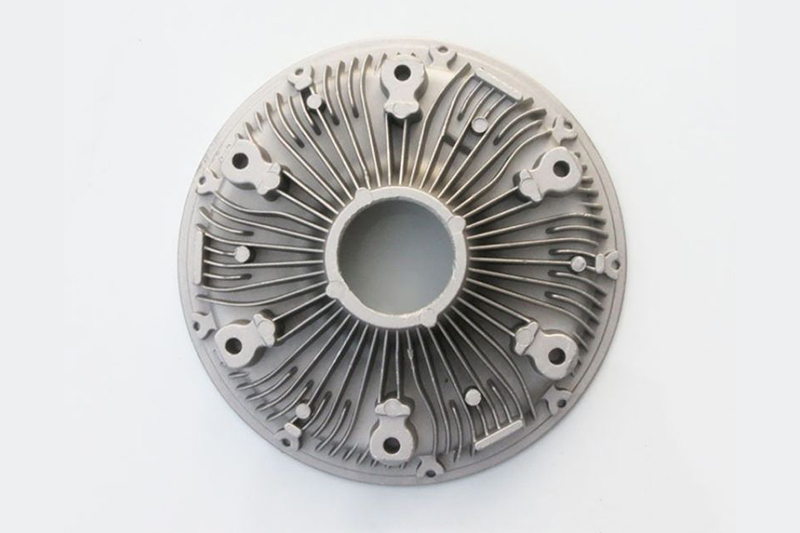

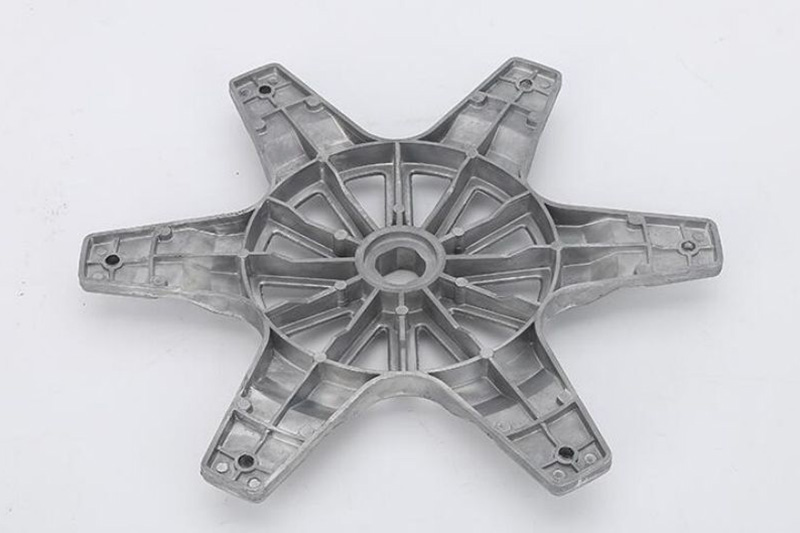

Hōʻikeʻike Die Casting Parts

Māhele Mea Paahana Rapid Prototype

Nā ʻāpana hoʻoheheʻe make nui

Mahele hoolei make make kino

Mahele Hoolei Make me ka Lapaau ole

Māhele Mea Paahana Prototype